Låkril Technologies imagines a future where drop-in industrial chemicals are produced from bio-based sugars rather than petroleum, thus alleviating reformulation costs and advancing rural biomanufacturing. Your coating solution, adhesive or SAP formulation can now be bio-based and meet your customer’s exacting requirements without breaking the bank.

MN Corn Podcast: Lakril Catalyzes Bioacrylic Acid from Corn - August 2024

Chris Nicholas, co-founder and president of Låkril Technologies, discusses the company’s advancements in developing a bioacrylic acid.

In the next 5 years, a critical need is a transition to low carbon chemicals at the lowest possible cost to society. Låkril Technologies sells catalyst and licenses processes utilizing a patent-pending bi-functional catalyst system to produce acrylic acid and the acrylate derivatives from bio-derived lactic acid. We work and partner with companies in the acrylics value chain to decarbonize this broad industry as our technology provides significant carbon reduction and can allow carbon sequestration during production of drop-in replacements. Contact us, and let’s get started on sustainable adhesives and coatings!

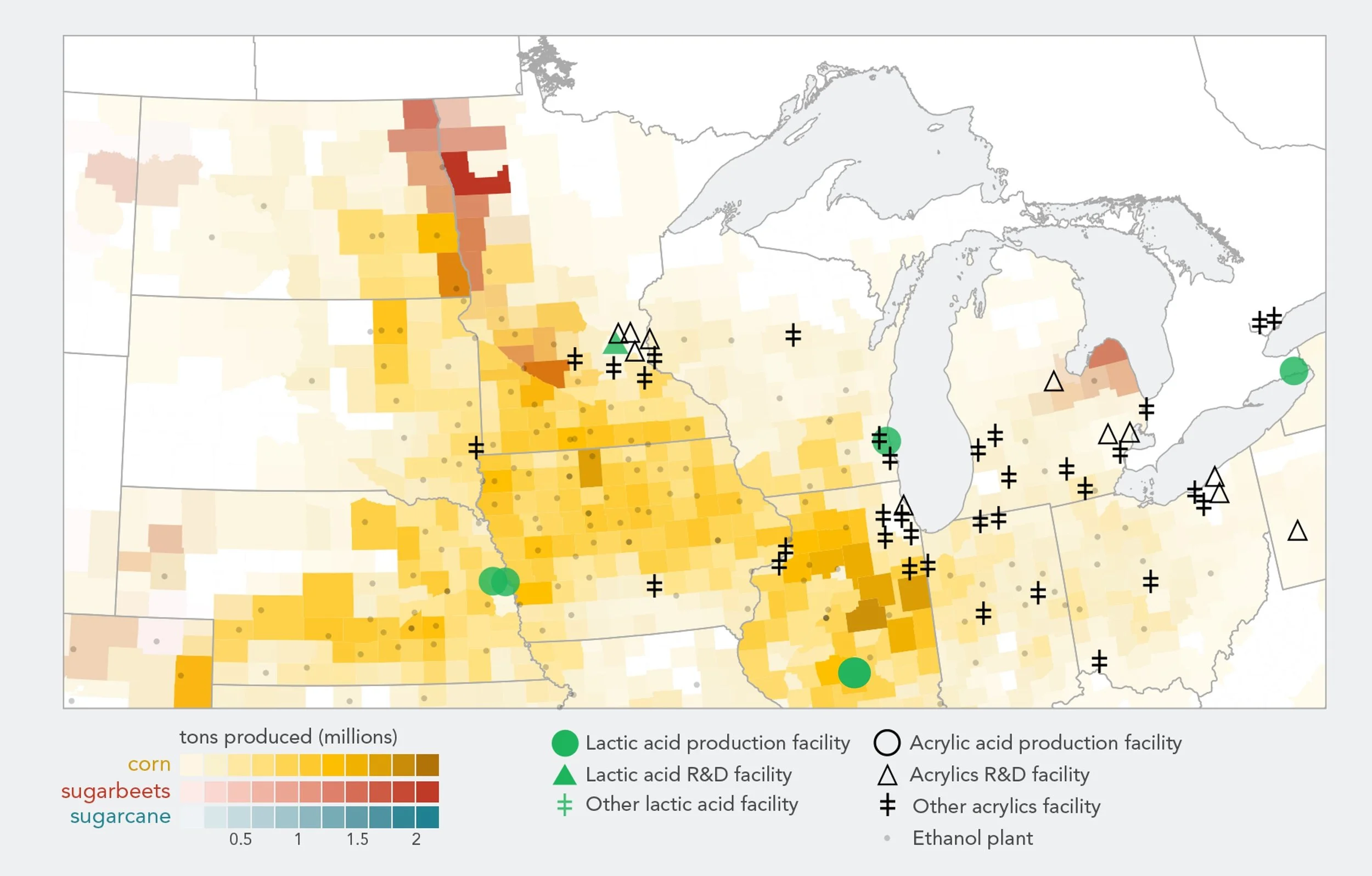

A competitive process to produce bio-based acrylics has long been sought by producers and end users, but cost-effective routes at scale with today’s petrochemicals have not been found before our discovery. Now, bio-based sugar sources (corn / cane / beets / cellulosic or 3rd gen sugars) can be utilized as sources to produce this high-volume chemical sustainably & economically with a low carbon footprint. We achieve high yields, and therefore attractive economics, in dehydrating lactate feeds to acrylic acid.

Our thermochemical technology platform provides outstanding yields of bio-based based acrylics from lactic acid, a molecule that has been produced commercially via fermentation since the 1880s. This large volume, low-cost feedstock coupled with our acrylic yields allows us to achieve our goal of giving sustainable materials a competitive edge by making them at incredibly low cost so that the transition to low carbon, bio-derived products is effortless for consumers and end users.

Research Partners

-

Illinois Corn Marketing Board

-

Indiana Corn Marketing Council

-

Corn Marketing Program of Michigan

-

United States Department of Agriculture

National Institute of Food and Agriculture - Phase II SBIR

Corn-Derived Ethyl Lactate for Sustainable Production of Biobased Acrylic Acid from High Water Content Feeds over FAU Zeolite-based Catalysts

-

United States Department of Energy

Office of Energy Efficiency & Renewable Energy - Phase I SBIR

Non-Oxidative Regeneration Processes for Na-FAU based catalysts for Decarbonization of the Acrylic Acid Industry through Biomanufacturing

-

National Science Foundation

Technology, Innovation and Partnerships (TIP) - Phase I STTR

Effect of Alcohol Concentration on Lactic to Acrylic Selectivity and Deactivation Rate over Na-FAU Zeolite Catalysts

-

-

Minnesota Corn Research & Promotion Council